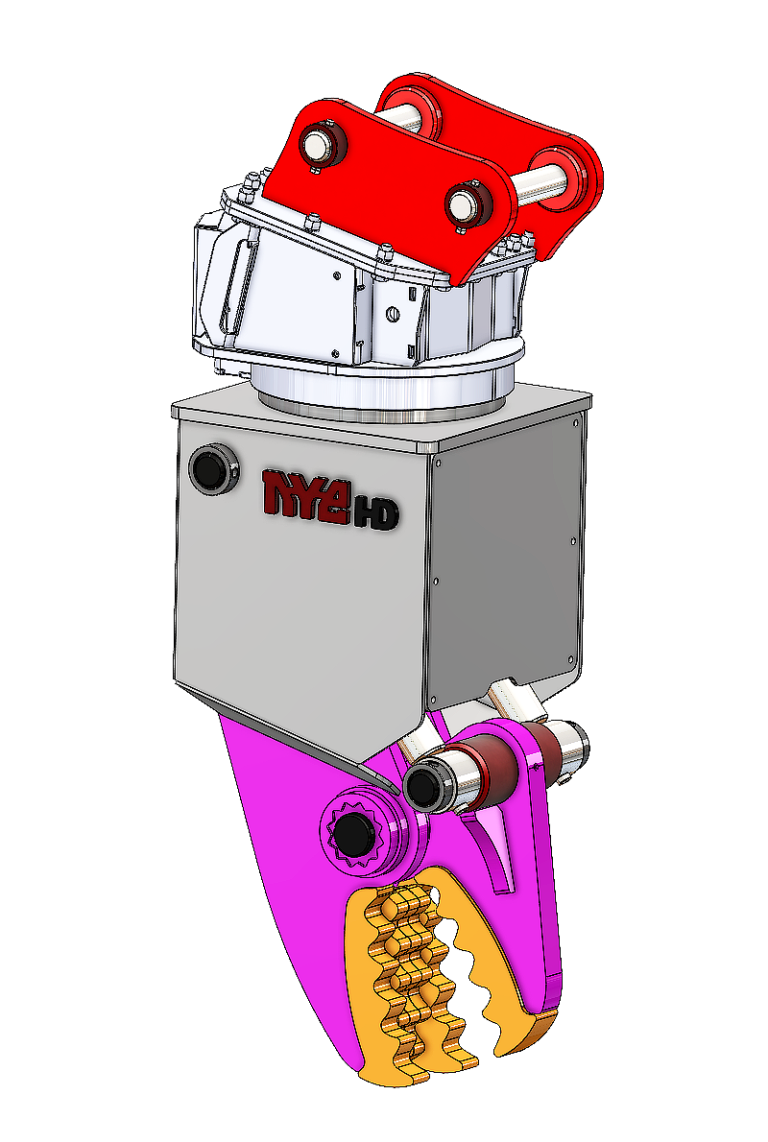

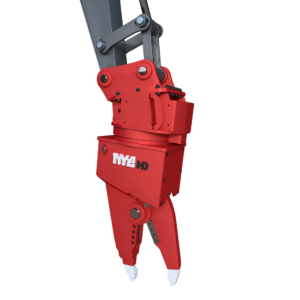

Engine Block Cracker

Designed to separate aluminum from ferrous metals in auto engine blocks and transmissions. A heavy duty crushing tool with continuous rotation and AR500 pulverizing teeth. The hydraulic rotator allows the operator to position the jaws over the block. Engine blocks, exhaust manifolds and crankshafts snap easily. In only a few seconds, the entire engine is reduced to a pile of “Corn Flakes” that can be swept over with a magnet to pull the ferrous out, leaving a clean pile of aluminum chips.

EBC – Engine Block Cracker

Quickly separate ferrous and nonferrous metals for easy recycling using a magnet.

EBC200

Lower section is fabricated from a T1 box, this provides strength and keeps the overall attachment weight down.

EBC200

Dual Hydraulic Cylinders – Two heavy duty, cylinders for double the crushing/gripping force.

Features

- Works well with or without a pin grabber coupler.

- Canine fangs for grasping and puncturing material

- Dual heavy duty cylinders.

- Continuous 360 degree hydraulic rotation.

- Precision Picking with intersecting tips.

- Super strong grip and twist action.

Specifications

| Carrier [x1000lbs] | Model | Weight kg [lb] | Tip Radius mm [in] |

|---|---|---|---|

| 16 - 24 t [35 - 53] | ECB200 | 2,050 [4,519] | 619 [24] |

| 22 - 28 t [48 - 62] | ECB250 | 2,300 [5,070] | 686 [27] |

| 26 - 38 t [57 - 84] | ECB350 | 2,450 [5,400] | 762 [30] |