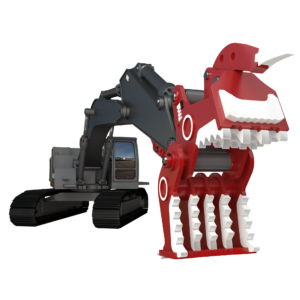

Thumbs – progressive-link

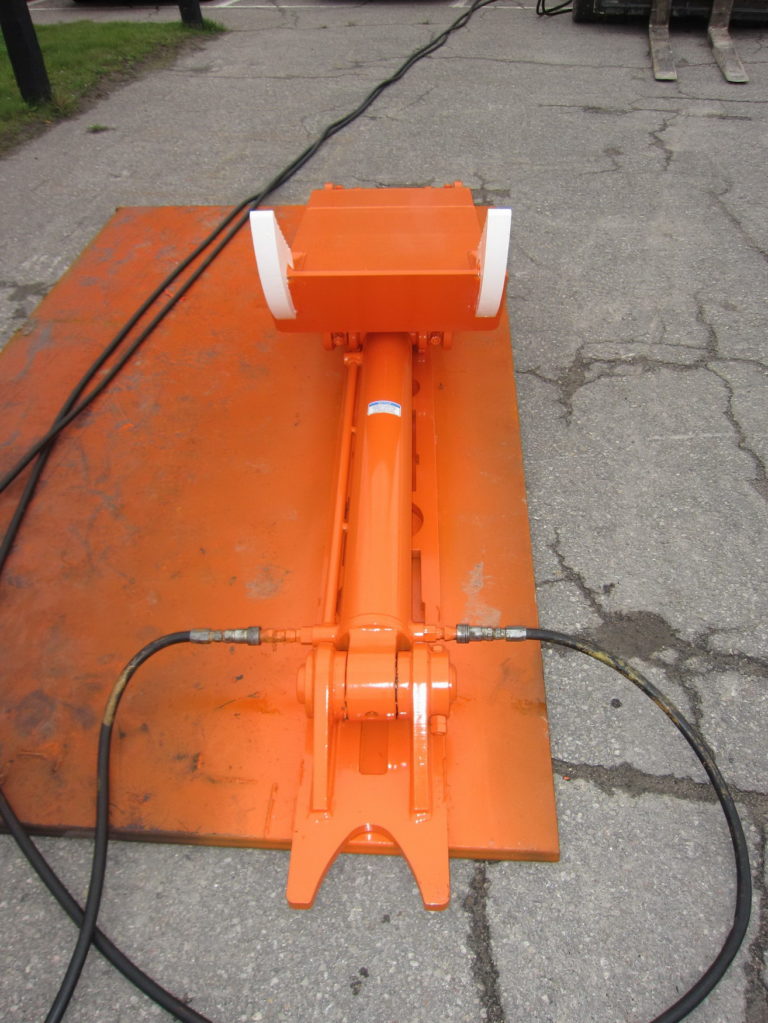

Nye PT1 Progressive Link (pro-link) weld-on thumbs feature a unique single unit design, manufactured for quick and easy installation.

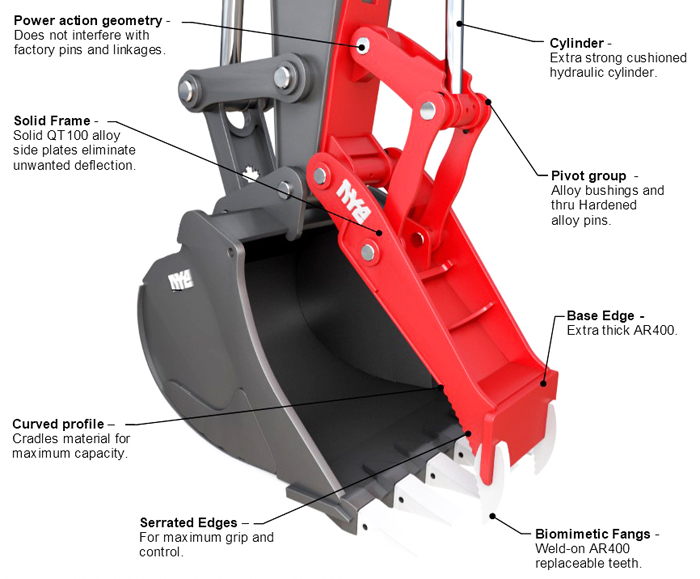

Heavy-duty biomimetic teeth, with serrations for extra grip, are welded solid to the base edge. The teeth mesh perfectly with your bucket because all Nye thumbs are custom built to suit your existing bucket and tooth arrangement.

The fully independent thumb linkage group is engineered to achieve 160° rotation. A simplified one-piece baseplate design means installation does not require disassembling or altering the factory pins or linkages.

Nye PT1 series pro-link thumbs are strong and versatile, built with quenched and tempered alloy steel to provide years of dependable service in the most demanding forestry and demolition applications.

Every Nye thumb is built to order so you get exactly the equipment you need – custom configurations are available to suit any application.

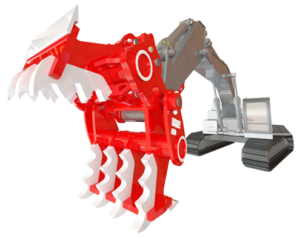

30PT1

- Does not interfere with factory pins and linkages.

- Solid QT100 alloy side plates eliminate unwanted deflection.

- Cradles material for maximum capacity.

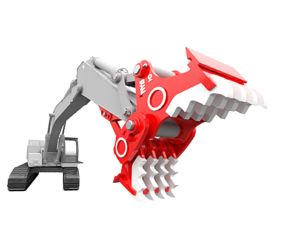

40PT1

- Single Plate design.

- Folds out of the way when not in use.

- Adjusts to any angle.

- Quench and Tempered Ally Steel construction.

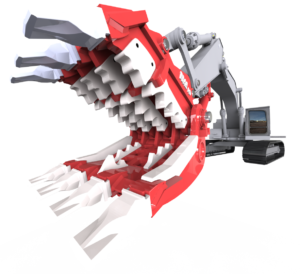

40PT1

- AR400 cutting edge style.

- Weld-on replaceable teeth.

- Quickly retracts out of the way.

- Spacing of teeth per clients’ specs.

Features

- Easy installation, no modification to the machine is required.

- Biomimetic fangs adapt easy to any bucket.

- Quenched & tempered and Abrasion Resistant alloy steel used throughout.

- No bucket or boom interference.

- Heavy construction.

Specifications

| Carrier | Model | Width mm [in] | Height kg [lb] |

|---|---|---|---|

| 16 - 24 t | 20PT1 | N/A | N/A |

| 22 - 28 t | 30PT1 | Configurable | 1,710 [67] |

| 26 -38 t | 40PT1 | Configurable | 1,800 [71] |

| 35 -50 t | 45PT1 | N/A | N/A |

- Specifications subject to change

- Units of measure kg [lb] and mm [in]